How to Start?

Step 1

Get Intercom Foam Bonding Systems -

Intercom Foam Bonding Systems consists of 3 key components: a tank of adhesive, a fluid hose, and an HVLP spray gun

Step 2

Just attach the hose to both the tank & the spray gun

Elevate the box

Connect your air line, and begin spraying

Contact us and our highly trained staff of experts will work with you to get you started with a Intercom Trial System.

What we need from You?

PCompressed Air Line

Get started in 10 minutes with intercom bonding expert guidance

Our Bonding experts are avaible to help you get started without loosing any time

We are also available online on all working days

Our Services

Delivery System

We design each system to meet the specific requirements of each client. These often include container size, spray stations, plant layout, rack location, ceiling height and any other unique necessities.

Process Flow Consulting

We consult with the necessary staff to develop better process flow and/or plant layout to gain the maximum benefits from INTERCOM.

R&D Laboratory Work

We establish laboratory projects to evaluate special applications. This can include specific product/substrate testing, determine the ideal method of application including process and custom formulations all to meet the client's requirements.

Automation

We offer custom automation solutions that incorporate adhesive application with process flow to achieve production goals set by our clients. We have the capabilities to design, engineer, build, and install a complete system.

Demonstration (Gravity, Pressurization, Pumping)

A sales person will visit a client's facility to learn about their application, manufacturing process and requirements. We'll show the unique performance characteristics of INTERCOM and how doing business with INTERCOM can benefit the client's operation.

Installation

We prefer installing the INTERCOM system so our client can focus on their production and other tasks at hand.

R & D

We establish laboratory projects to evaluate special applications. This can include specific product/substrate testing, determine the ideal method of application including process and custom formulations all to meet the client's requirements.

Automation

We offer custom automation solutions that incorporate adhesive application with process flow to achieve production goals set by our clients. We have the capabilities to design, engineer, build, and install a complete system.

Training

Our staff is committed to working with all departments to ensure a successful implementation takes place. Management, maintenance, production, receiving, and purchasing are all involved at different levels and could benefit from our assistance

Application Expertise

Our industry expertise is acquired by investing countless hours in manufacturing plants, learning the specific applications for each industry and then using this knowledge to create effective solutions. For example, the processes and methods used in furniture fabrication are not necessarily applicable for use in the automotive industry. It's an enormous benefit to bring our clients.

Visits

These visits are important refresher courses and give us the opportunity to offer additional training and consult with staff to develop better means as the client's business evolves.

Telephone

When we receive a call, the person who first answers will be capable of accommodating any requests. Whether it’s placing an order, requesting an SDS, addressing a technical question, or help with a spray gun, a client’s requirements are always met quickly and without delay

Web

It's a great place to learn about INTERCOM and our capabilities. We continue to expand the site to provide information our clients can use. All technical data sheets, SDSs, installation instructions, spray gun guide, ISO Certificate, etc. are available for download in PDF format

Same Day Shipping

No Lead Times! We stock everything you need for the complete INTERCOM system including spray guns, accessories, and system components.

Order Confirmation

Receive an automatic notification when our warehouse is preparing your order and a shipping confirmation with tracking number when your order is on its way. “What’s the status of my order?” You’ll never have to ask that question again.

Inventory Management

Take advantage of having us manage your INTERCOM inventory through one or all of our proven systems - Automatic Order Reminder (TM), Scheduled Inventory Management (TM), INTERCOM WebInventory System (TM).

Order Document Management

All your documents are immediately available upon request in PDF format.

Payment Options

Electronic Funds Transfer (EFT), Wire Transfer, and Credit Card (Visa, MasterCard, American Express) are our accepted methods for quick payment.

Benefits

No fluid handling

No adhesive contamination

No maintenance

Consistent operation

Low startup investment

It’s SIMPLE!

Why Intercom?

We’re the only adhesive company that is 100% dedicated to water based technology, and we focus entirely on our area of expertise. Other adhesive companies produce products for many industries, trying to be everything to everyone. Our focus is very direct, resulting in products that perform better than all others.

Made in Italy

Thanks to strong R&D & A 30+ YEARS OF EXPERINCE , we are constantly adapting and creating products to meet your every need. Selecting a so called “me too” product adds too much risk to your business.

Proven

Countless years of development, numerous amazing products, and many years of proven market acceptance ensure your long-term success.

Wide Range

With 200+ formulations, we can recommend a product that will fit your specific need today and easily adjust as your needs evolve tomorrow.

The Intercom Team

Expertise to guide and assist you with applications, production processes, inventory management and much more. Always professional + timely, we never miss ship dates or an opportunity to serve you.

Manual Brush or Roll

Benefits

-

Low start up cost.

-

Simple to set up and use.

-

Requires no training

-

Ideal for clients that have very limited need for adhesive.

Limitations

Difficult to control application amount, creating waste.

Low initial tack vs. spraying.

Brushes or rollers are typically discarded after use.

Application is time consuming.

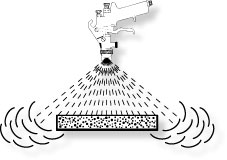

Manual Spray

Benefits

-

Instant tack.

-

Low startup investment.

-

Complete control over where adhesive is applied.

-

Ideal with any delivery method.

Limitations

Basic knowledge of spray guns is required.

Requires training so operators use spray gun correctly.

Possible overspray if used incorrectly. (Not applicable if using INTERCOM Overspray Free Technology)

Automatic Spray

Benefits

-

Instant tack.

-

Consistent, and quick means of applying INTERCOM.

-

Eliminates the human factor.

-

Able to cover large surface areas quickly.

-

Ideal for large runs of a particular item or unit.

Limitations

Requires substantial equipment investment.

System expertise required in regards to operation and maintenance.

Lacks flexibility when used with short runs.

Requires adjustment when part size changes.

Can require a substantial amount of production floor space.

Possible overspray if used incorrectly. (Not applicable if using INTERCOM Overspray Free Technology)

Automatic Roll Coater

Benefits

-

Ideal for flat surfaces.

-

Single sided application.

-

Consistent, and quick means of applying INTERCOM.

-

Eliminates the human factor.

-

Very flexible when part thickness changes.

-

Able to cover large surface areas VERY fast.

-

Easy operation and maintenance.

-

Ensures consistent application amount from part to part.

Limitations

Large initial investment.

Not ideally suitable for substrates needing adhesive on multiple surfaces.

Requires a substantial amount of production floor space.

Less instant tack as compared to spray methods.

System expertise required in regards to operation and maintenance.

Requires cleaning at end of day.

Manual Spray Technology Training

Despite the ongoing interest in automation, manual spraying is still the most used and remains a very effective method for applying Intercom. Providing the system is installed correctly, spray guns are set properly, and operators use proven techniques, clients can benefit greatly.

Installation + Maintenance

-

Install an air regulator for each spray gun

-

Install air regulators out of the sprayers' reach.

-

Replace damaged parts of the spray gun.

-

Inspect air hoses and air connections regularly. A 1/4" air leak can cost thousands per year in electricity alone.

Clean and maintain the spray gun according to the manufacturers' recommendations.

Spray Gun Settings

-

Minimize fluid volume coming from the spray gun.

-

Control atomization air pressure in relation to adhesive volume.

-

Match the spray gun and settings (nozzle, needle, air cap) with the adhesive. Failure to choose the correct equipment generally results in lower efficiencies and increased adhesive costs through waste and overspray.

Sprayer / User

-

Increase spray gun transfer efficiency or product yield by implementing more consistent spraying techniques.

-

Maintain the proper spraying distance and angle from the substrate.

-

Download the above documents and post in the spray area for reference.

What is Overspray?

In any pneumatic spray application, overspray is an area of concern that should be addressed early on. Fortunately if it does occur, it’s easily remedied through the use of a High Volume Low Pressure (HVLP) spray gun and operator training.

When we talk about overspray, we’re referring to any portion of sprayed material that doesn’t land on the target substrate, whether it lands beyond the border of the target substrate, or is dispersed into the air. Overspray results in wasted material, and effects the cleanliness of the spray area, so it’s logical to take the necessary steps to minimize it.

Using the Correct Equipment

Having the correct spray gun is the first, and most important step to take in minimizing overspray. INTERCOM HVLP Spray Guns allow spray operators to properly atomize the adhesive using low air pressure settings (most spray gun manufacturers offer similar HVLP models). Doing so will maximize product yield, eliminate waste, and help to keep the work environment clean.

The second important step is to install an air pressure regulator between your air compressor and each spray gun to prevent spray operators from adjusting atomization air beyond the desired setting.

Causes + Solutions

Once we have the right equipment and a regulator in place, there are a few very simple steps we can take to eliminate overspray and waste. By making simple adjustments to the spray gun settings, and working with the spray operators on basic technique, we can all but eliminate overspray as a concern.

Detailed below are the 4 causes along with solutions for overspray.

Go to: Intercom {Overspray Free} Technology

Air Pressure Too High {Spray Gun Setting}

CAUSE:

When using high air pressures a "bounce effect" and "cloud" will be created. INTERCOM is naturally tacky and requires low air pressure for proper atomization.

SOLUTION:

Reduce Air Pressure

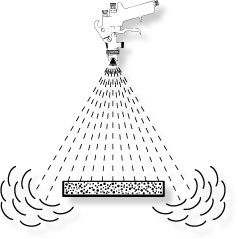

Spray Pattern Too Wide {Spray Gun Setting}

CAUSE:

We recommend a narrow spray pattern so the operator can better control the application of adhesive. A wide spray pattern will cause the operator to miss the substrate causing overspray and mess.

SOLUTION:

Reduce Pattern Width

Incorrect Angle of Spray {Operator Technique}

CAUSE:

It is recommended that the spray gun be held perpendicular (at 90 degree angle) to the substrate. As the angle decreases, the adhesive will "ricochet" off or miss the substrate causing overspray.

SOLUTION:

Spray at 90° Angle

Spraying Too Far From Substrate {Operator Technique}

CAUSE:

The spray gun should be held at a distance between 4"-10" (10cm-25cm) from the substrate when applying INTERCOM. As the distance between the spray gun and the substrate increases, so does the width of the spray pattern causing overspray.

SOLUTION:

Spray Closer to Substrate

Basic Knowledge

-

When looking at the bond strength of adhesives, it is important to differentiate the strength of the bond when the substrates are initially bonded from the strength of the bond after the adhesive has cured - Tack vs. Cure.

-

This page is designed to address the initial bond strength. As we compare the initial bond strength of INTERCOM vs. a solvent based adhesive, it is important to understand tack vs. cure. INTERCOM will tack instantly, while a solvent based adhesive will cure instantly.

-

We find that the instant tack offered by INTERCOM allows for much more versatility and speed in your production and processes when compared to the instant cure of a solvent based adhesive.

Shear Strength

When we refer to shear strength, we refer to the strength of the adhesive bond while attempting to slide 2 parallel bonded substrates past each other. Both INTERCOM and solvent based adhesives offer instant shear strength.

Pull Strength

Pull strength refers to the strength of the bond when pulling the substrates in a direction that is perpendicular to the bonded surface. Both INTERCOM and solvent based adhesives offer instant pull strength.

Peel Strength

Peel strength is determined by the ability of the adhesive to resist separation when a substrate is peeled up from the edge to remove it from the material to which it has been bonded. This is where we find the key difference between INTERCOM and solvent based adhesives. INTERCOM is designed to allow the substrates to be peeled and repositioned while the adhesive is still wet. This will allow the operators to correctly position and reposition the substrates without damaging them, or having to apply more adhesive. This provides numerous advantages that can help with speed, process, and overall quality. Solvent based adhesives do not allow for this. It is again important to note that once INTERCOM has cured, peeling will result in destruction of the substrates.

Intermediate Bulk Container (IBC) (1000kg Net)

| Gross | Tare | Net |

|---|---|---|

| 2332 lb | 1055 kg | 121 lb | 55 kg | 2200 lb | 1000kg |

| Height | Width | Depth |

| 46 in | 117 cm | 40 in | 102 cm | 48 in | 122 cm |

Due to the lack of consistent supply of IBCs with the same valves, it is possible to receive one of several different valve types. It's important to understand each type so that the proper connection can be made for use.

Box (20kg Net)

| Gross | Tare | Net |

|---|---|---|

| 46.42 lb | 21.10 kg | 2.42 lb | 1.10 kg | 44 lb | 20 kg |

| Height | Width | Depth |

| 12 in | 30.5 cm | 12.25 in | 31 cm | 12.25 in | 31 cm |

Unlimited Options

The Intercom line of water based adhesives is available in a variety of standard color options, depending on the formulation. We offer these choices to help our clients fill a specific need in regards to application and process. Some clients like to be able to see the adhesive being applied, want to display the product to end buyers, while others don't.

We also have the capability of producing our products with a custom color if one of our standard options is not ideal for a client’s application.

Things to Consider

Color -

whether a custom color is required for matching a substrate or just as a visual aid, we work closely with each client for a unique result that's repeatable. The client must understand that the color of the product may vary between batches due to variations in color of the underlying raw materials.

Product Volume -

A custom color is best suited for a client who is able to commit to and use 2000kgs or 500 gallons.

Custom Color Requirements

Approve and implement the appropriate INTERCOM formulation in a standard color.

Determine if the purchase volume fulfills the minimum batch size for a custom color.

Evaluate custom color samples of the INTERCOM product.

Approve custom color.

Place POs in advance as custom colored products are made-to-order and require additional time to schedule production.

FAQ

1Is INTERCOM ECOSTICK expensive?

No. Our customers enjoy the lowest adhesive cost per bonded part.

2 How long must I wait after spraying, before placing parts together?

No waiting! You can stick the parts together after spraying for immediate bond. It's quite different than water based adhesives from other manufacturers.

3How strong is the INTERCOM ECOSTICK bond?

Strongest in the industry. The bond has been tested at more than twice the strength of traditional solvent based adhesives.

4 Does INTERCOM ECOSTICK contain solvents?

No. INTERCOM ECOSTICK is a water based adhesive that is solvent free.

5 Does INTERCOM ECOSTICK contain ammonia or other Hazardous Air Pollutants?

NO. INTERCOM ECOSTICK does not contain any ammonia or other Hazardous Air Pollutants.

6 Who would design the system for my company?

We design each system to meet the specific requirements of each customer. Just leave it up to us.

7 What’s the easiest way to begin?

Contact US

Surfaces

Bonding foams

Fabrics

Virtually any porous substrates